9440 IR-U Infrared Preheating robot

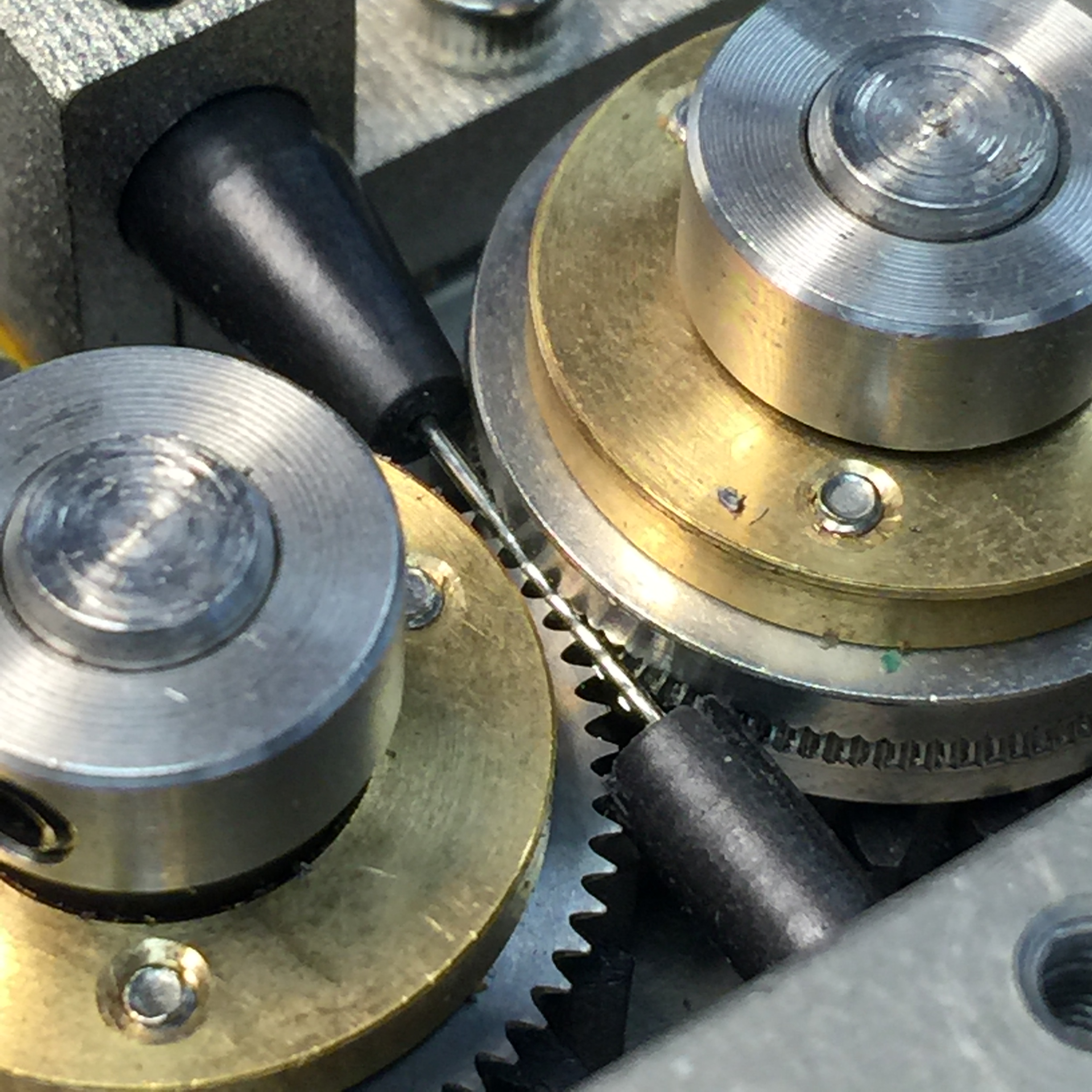

The 9440 IR-U series of Soldering Robots feature a robust Hot Iron system with a superior closed loop temperature sensor. The Hot Iron is capable of delivering and maintaining a tip temperature with industry leading stability and accuracy. Two fine-toothed gears work to pull Solder from the Solder Spool while also perforating the surface of the Solder Wire to allow for better out gassing of the Flux Core.

A key feature of this system is an integrated IR Preheat Station with 4 selectable preheat “zones” capable of achieving a temperature of 300°C

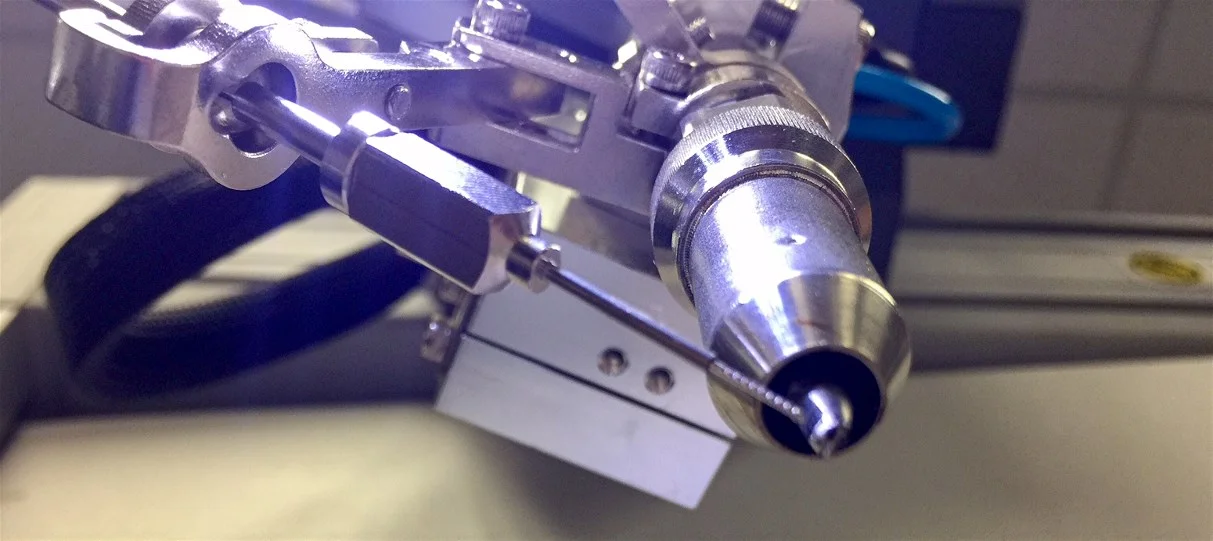

There are two laser thermal probes located on opposite sides of the soldering area targeting the preheating zone and the product being heated. These probes are adjustable and are used to provide thermal feedback information to the system allowing for greater process control.

Newly designed technologies also featured on this system include: 371T Solder Feeder and Tip Pressure Monitoring System.

All systems come standard with a 200W Power Supply capable of delivering temperatures of up to 500°C, automatic solder feeder, tip cleaning station, positive tip location, and localized fume extraction tube.

Heated Nitrogen Kits, Vision Guidance Systems, Color CCD "Witness Cameras", Light Screen / Safety Enclosures, and Automatic Tip Correction are available options.

SYSTEM SPECIFICATIONS

VOLTAGE: 110V AC

POWER SUPPLY: 200W

TEMPERATURE RANGE: 50-500°C

AXIS: 4

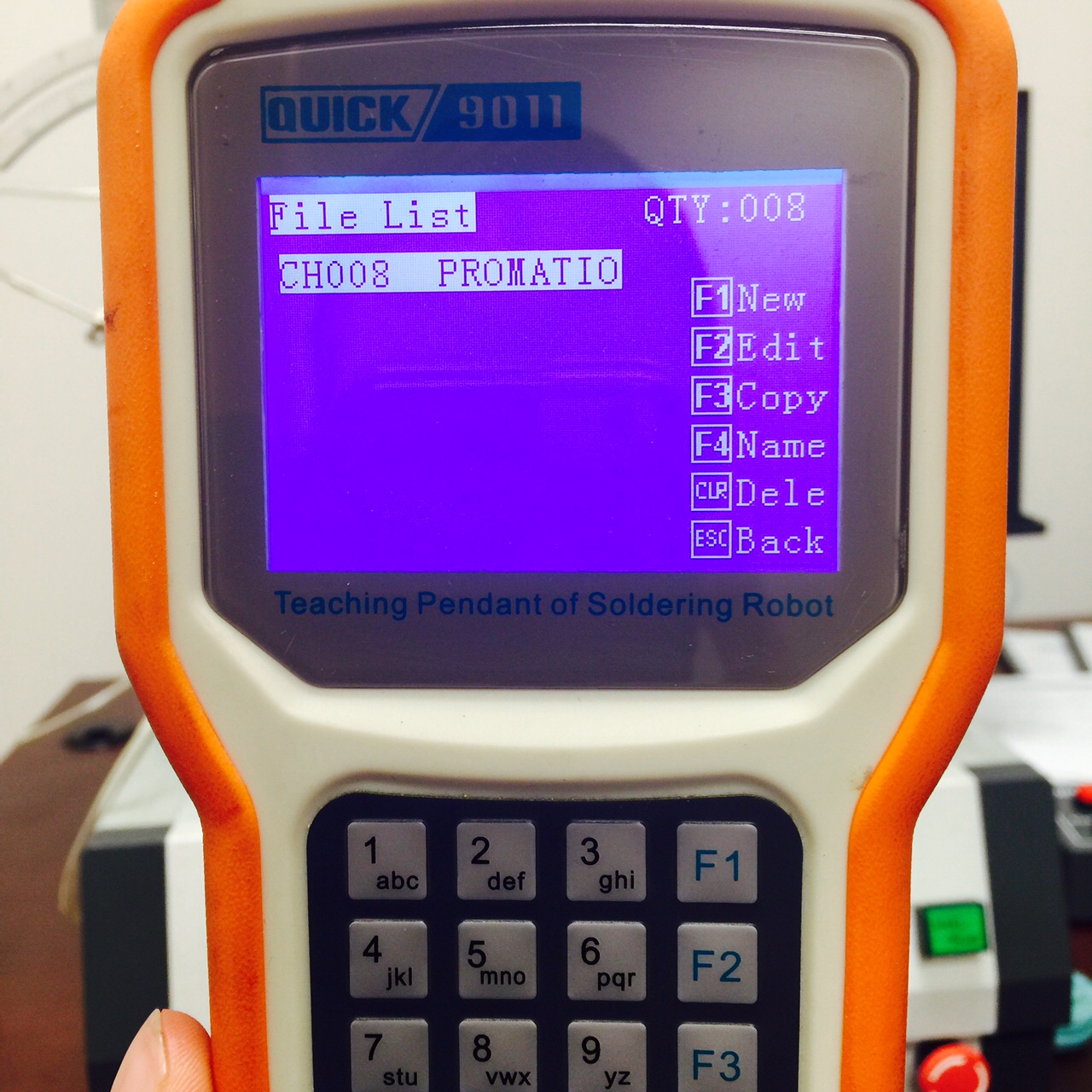

ON BOARD FILE STORAGE 255 Programs Max

COMMAND PER PROGRAM STORAGE CAPACITY 60000 Commands Max

SOLDER WIRE DIAMETER (mm): 0.6, 0.8, 1.0

PREHEATING RANGE: 50°C-300°C

MACHINE SIZE (WxDxH): 860x 1125x 870mm

WORK TABLE 22lbs

HEAD 4lbs

MOVEMENT RANGE:

X-AXIS 400mm

Y-AXIS 400mm

Z-AXIS 100mm

R-AXIS 300°

SPEED RANGE:

X-AXIS 0.1-600mm/s

Y-AXIS 0.1-600mm/s

Z-AXIS 0.1-200mm/s

R-AXIS 0.1-600mm/s

REPEAT ACCURACY:

X-AXIS ±0.02mm

Y-AXIS ±0.02mm

Z-AXIS ±0.02mm

R-AXIS ±0.02°

STEPPER RESOLUTION:

X-AXIS 0.01mm

Y-AXIS 0.01mm

Z-AXIS 0.01mm

R-AXIS 0.01°

ENVIRONMENTAL CONDITIONS:

TEMPERATURE 0-40°C

HUMIDITY 20-90%