SOLDERING ROBOTS

9434 vision

Call for pricing

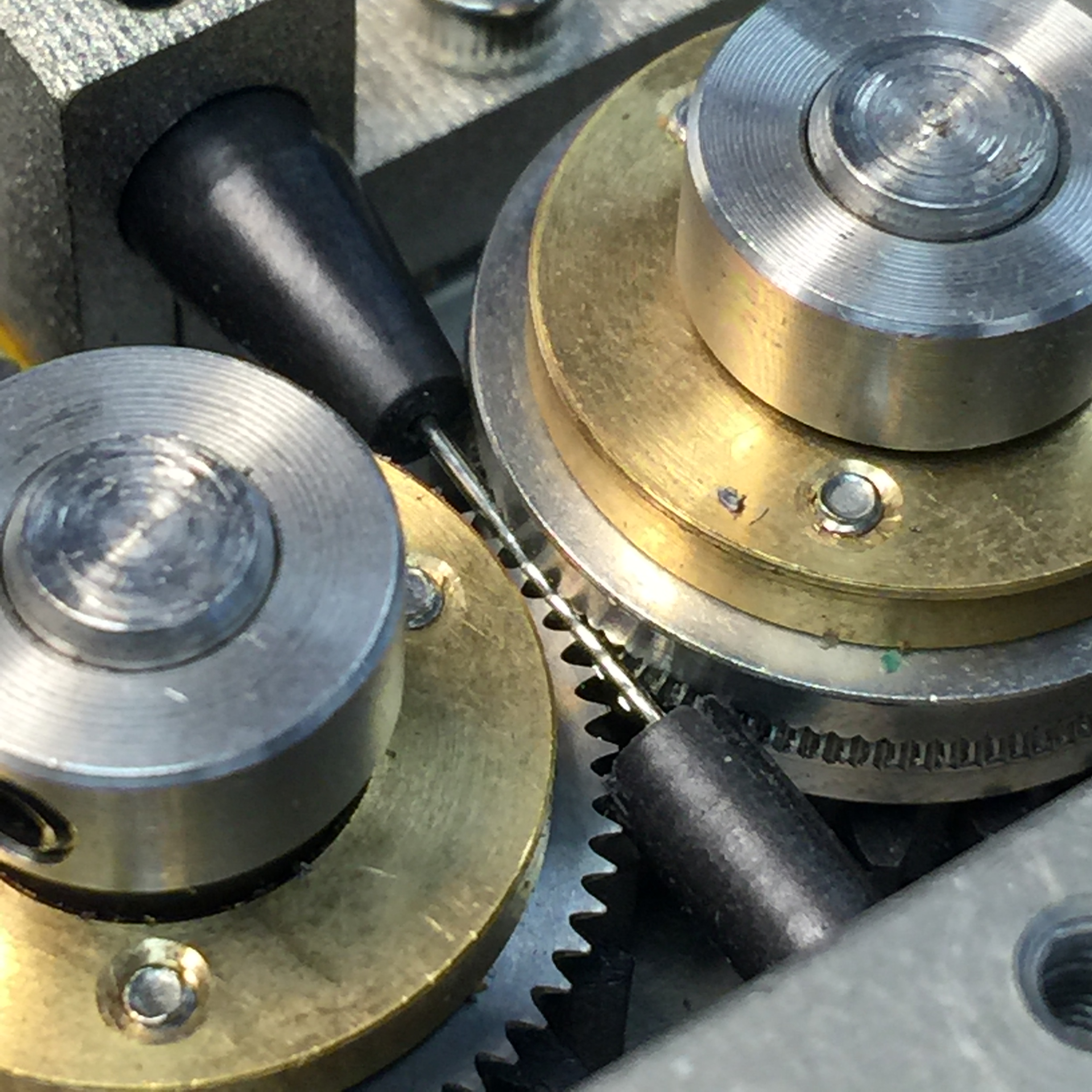

The QUICK 9434 Vision series of Soldering Robots feature a robust Hot Iron system with a superior closed loop temperature sensor capable of delivering and maintaining a tip temperature with industry leading stability and accuracy. Two fine-toothed gears work to pull Solder from the Solder Spool while also perforating the surface of the Solder Wire to allow for better out gassing of the Flux Core.

The vision feature allows for process forgiveness by allowing the machine to make small tip location adjustments on the fly. This can be helpful when working with materials that may not always be placed in the exact same position on the board every time the robot fixture is loaded.

System specifications:

VOLTAGE: 100-240V AC

HEATING POWER: 150W

TEMPERATURE RANGE: 50-500° (as per working mode)

AXIS: 4

WORK TABLE MAX LOAD: 18lbs

HEAD MAX LOAD: 4lbs

ON BOARD FILE STORAGE: 255 Programs Max

COMMAND PER PROGRAM STORAGE CAPACITY: 60000 Commands Max

SOLDER WIRE DIAMETER: 0.3, 0.5, 0.6, 0.8, 1.0, 1.2mm

SIZE WxDxH: 570x570x790mm

WEIGHT: 110lbs

MOVEMENT RANGE:

X-AXIS: 400mm

Y-AXIS: 400mm

Z-AXIS: 100mm

R-AXIS: 300°

SPEED RANGE:

X-AXIS: 0.1-600mm/sec

Y-AXIS: 0.1-600mm/sec

Z-AXIS: 0.1-200mm/sec

R-AXIS: 0.1-600°/sec

REPEAT ACCURACY:

X-AXIS: ±0.02mm

Y-AXIS: ±0.02mm

Z-AXIS: ±0.02mm

R-AXIS: ±0.02°

RESOLUTION:

X-AXIS: 0.01mm

Y-AXIS: 0.01mm

Z-AXIS: 0.01mm

R-AXIS: 0.01°

ENVIRONMENTAL CONDITIONS:

TEMPERATURE: 0-40°C

HUMIDITY: 20%-90% (no condensing)